Custom project and obsolete parts reengineering

In more than ten years we have manufactured over 11.000 devices installed all around the world in trains, planes, vessels and radio communication systems. Every product is designed, developed, built and tested to guarantee robustness, reliability and endurance in demanding applications characterised by high humidity, vibrations, heat drops, etc.

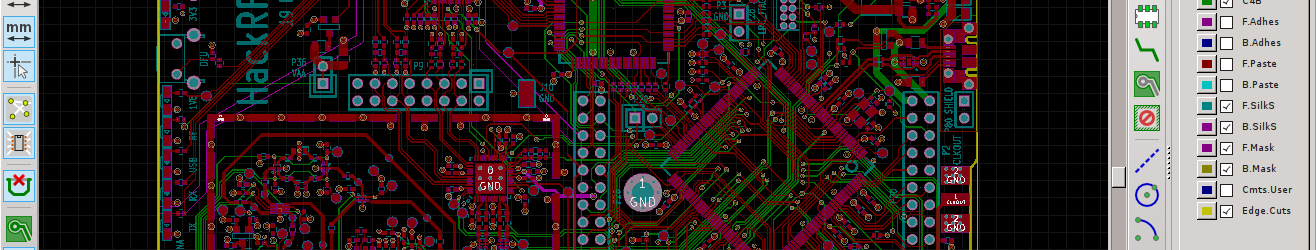

Custom projects

As engineers and manufacturers of power conversion systems, we are always focused to find the best solutions for our customers, at the best price.

The added value of any MCPOWER product is its custom design. All our products are developed in synergy with our customers, from the design-review of their technical needs up to the definition of the electrical requirements. This permits to meet all the technical needs and to design high quality products with reduced cost and market time.

Obsolete devices reengineering

Custom design allows to replace obsolete out-of-market devices with pieces that are equivalent in terms both of performances than electrical and mechanical interfaces; this approach permits not to redesign the whole system in order to adapt commercial devices and gives further advantages in terms of spare parts availability and life time extension.

Commissioning and certifications

For any project, MCPOWER delivers a feasibility study, a project plan and a production plan to point out potential critical areas or path.

Any product is delivered with a commissioning report, a test type report and all related certificazions such as:

- EN 50155